|

阅读:3346 ,发布于2023/11/15 10:47

In this case study, we talk about CSBio's peptide synthesizer platform

and knowledge that allows companies to utilize our peptide synthesizers during

the early days of drug discovery, all way through commerical scale

manufacturing

Introduction

When a multinational pharmaceutical company initiated their in-house

manufacturing of peptides in the early phases of drug discovery, they came to

CSBio for their instrumentation needs. As a manufacturer of custom peptide

synthesizers from small scale to large scale manufacturing, this pharmaceutical

company knew they had a partner that could meet all of their instrumentation

needs from drug discovery to commercial manufacturing for process development

and scale up ease.

Brief

During drug discovery

for lead optimization, this pharmaceutical company determined they needed a

reliable small scale synthesizer to produce peptide analogs which would be used

in testing to determine the best analog for scale-up and clinical trials. As a

fair amount of material would be required for this testing (20-100 mg) and

flexibility in the synthesis protocol was important, they turned to the CS136

which enabled their discovery lab to rapidly synthesize dozens of peptide

analogs in a short amount of time with enough material produced for multiple

tests and assays.

CSBio

CS136M

Once a primary peptide drug candidate was selected, the peptide chemists

at this pharmaceutical company were tasked with making a continuous supply of

high purity peptide for toxicological studies, PK studies, formulation work and

additional assay testing. Grams of peptide were now required, so the

pharmaceutical company set up a CS536 system in the process development

laboratory to accomplish this task.

To manage the scale up transition from small scale to large scale

manufacturing, a second CS536 system was purchased shortly thereafter and

customized with both a 180° inversion mixing system and overhead stirring. This

unique design was a collaboration between CSBio design engineers and the

pharmaceutical company to add an extra layer of confidence in their methodology

as they prepared for the scale up transition from inversion mixing to overhead

mixing, which would ultimately be required for large scale manufacturing of the

peptide drug.

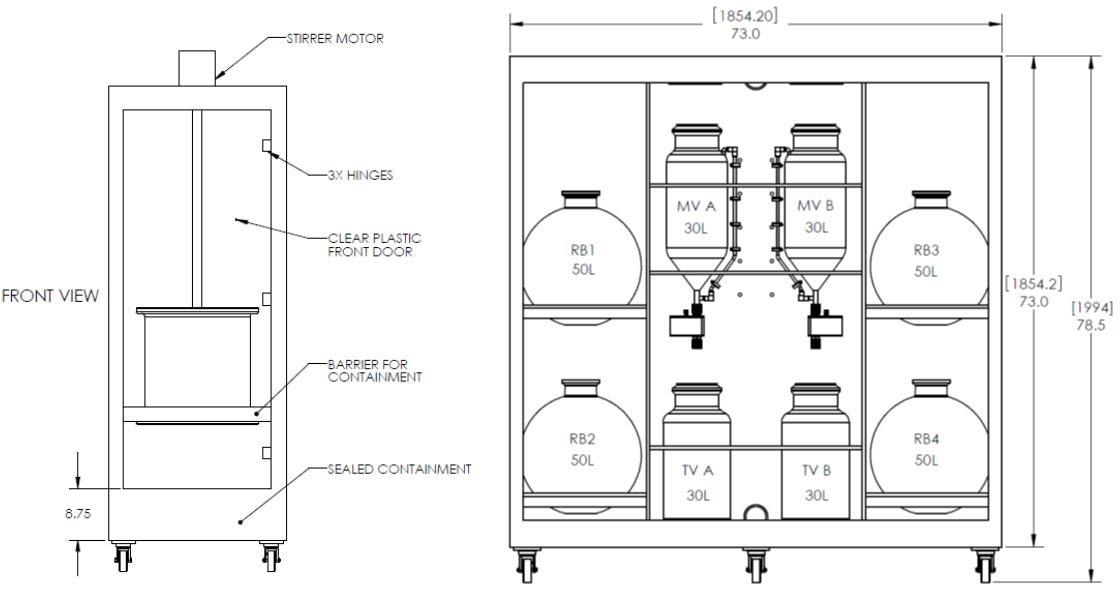

Custom

Designed CSBio CS936

As the pharmaceutical

company moved into late stage clinical trials the new task at hand was scaling

up for commercial manufacturing. CSBio and the pharmaceutical company worked

closely together to design a CS936 production scale synthesizer that would suit

their exact large scale production requirements. It was imperative that the

transition from R&D scale to process scale to manufacturing was as seamless

as possible. As all CSBio synthesis systems use the same 21 CFR Part 11

compliant CSPEP software®, the transition from milligrams to grams to kilograms

was made much easier as the synthesis protocols could be transferred up the

production scale.

The CS936 unit was synthesizing

manufacturing runs immediately upon installation/operational qualification as

there was virtually no learning curve for the manufacturing group. CSBio has

purposely designed our systems to make scale up from R&D to commercial

manufacturing as easy as possible.

Conclusion

CSBio provides customers with peptide synthesizers that fit their exact

needs throughout the lifecycle, whether it’s during early drug discovery or

late stage commercial manufacturing. By working intimately with customers

coupled with over 30 years of peptide and instrumentation knowledge, customers

can trust they have a partner to ensure a successful project.

Interested in any of our peptide synthesizers? Get in touch with us.

|

沪公网安备 31011502005552号

沪ICP备13005633号-1

沪公网安备 31011502005552号

沪ICP备13005633号-1