|

The role of temperature in Solid

Phase Peptide Synthesis (SPPS)

In this case

study, we evaluate the effect of

temperature on the speed of synthesis

and crude purity

Introduction

When performing solid phase peptide

synthesis there are multiple factors

that contribute to the quality of the

produced peptide, the speed of the

synthesis, and solvent consumption. A

few factors include the coupling

chemistry, the amount of time for

deprotection and coupling phases as well

as the temperature of the synthesis

environment. A common question

researchers ask when inquiring about

automated peptide synthesizers is: “What

can I expect my crude purity to be?” and

“How long will it take to make a

peptide?”

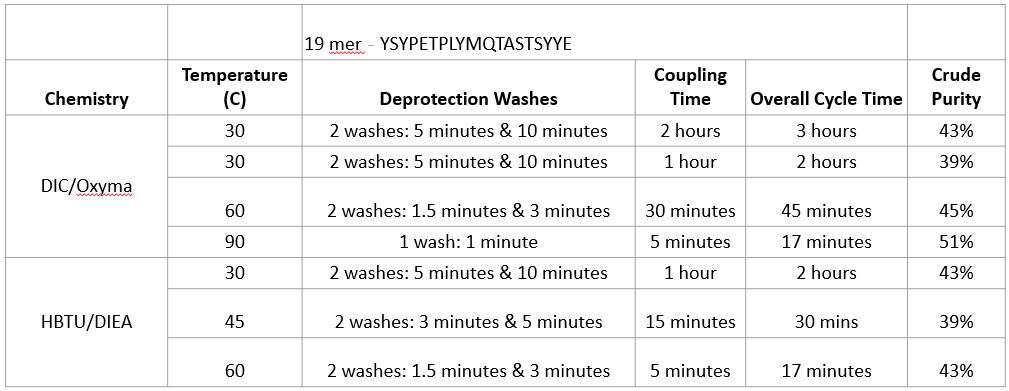

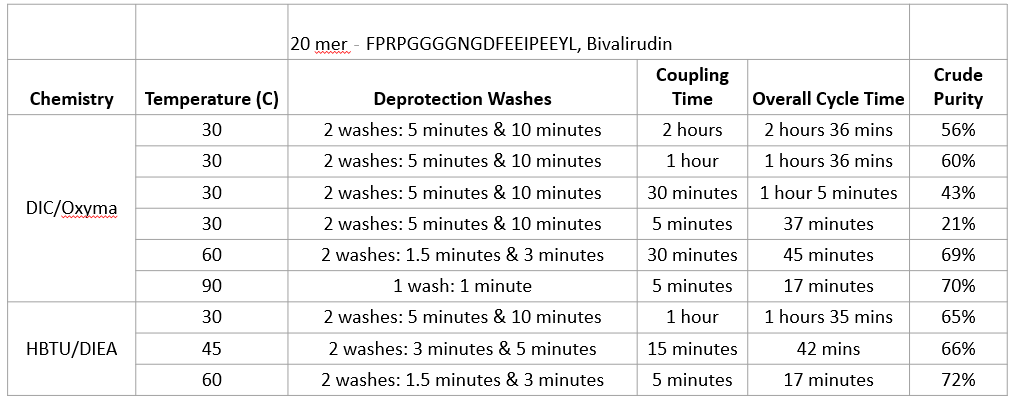

In this case study, we break down how

the two most common chemistries used for

SPPS at different temperatures and

deprotection and coupling durations

affect peptide crude purity.

Brief

Solid phase peptide synthesis requires

a series of steps for each amino acid to

build the peptide chain: Deprotection,

washing, coupling, washing, repeat. At

CSBio we synthesized two peptides with

both DIC and HBTU chemistry with

different temperatures and cycles times,

and evaluated the effect on crude

purity.

All peptides were synthesized on Rink

amide resin at a 0.2 mmol scale on a

CSBio II Peptide Synthesizer. The

temperature was set on the CSBio II

Peptide Synthesizer, maintaining the

temperature of both the reaction vessel

as well as the pre-solvent delivery

(both the wash solvent and deprotection

solution are preheated prior to delivery

to the reaction vessel) at the

temperature noted in the table.

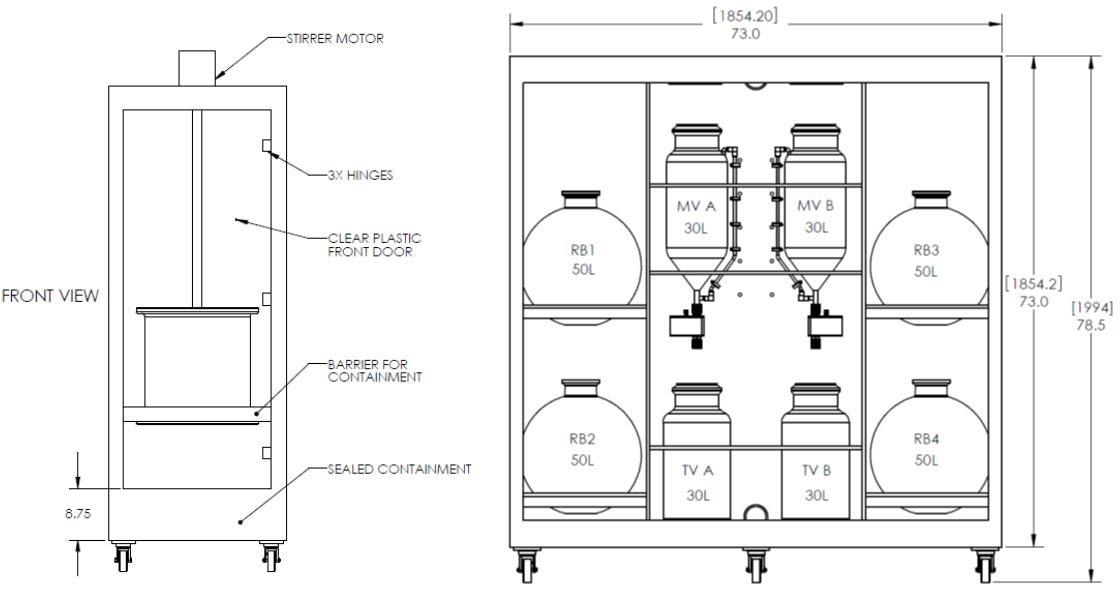

CSBio II Peptide Synthesizer

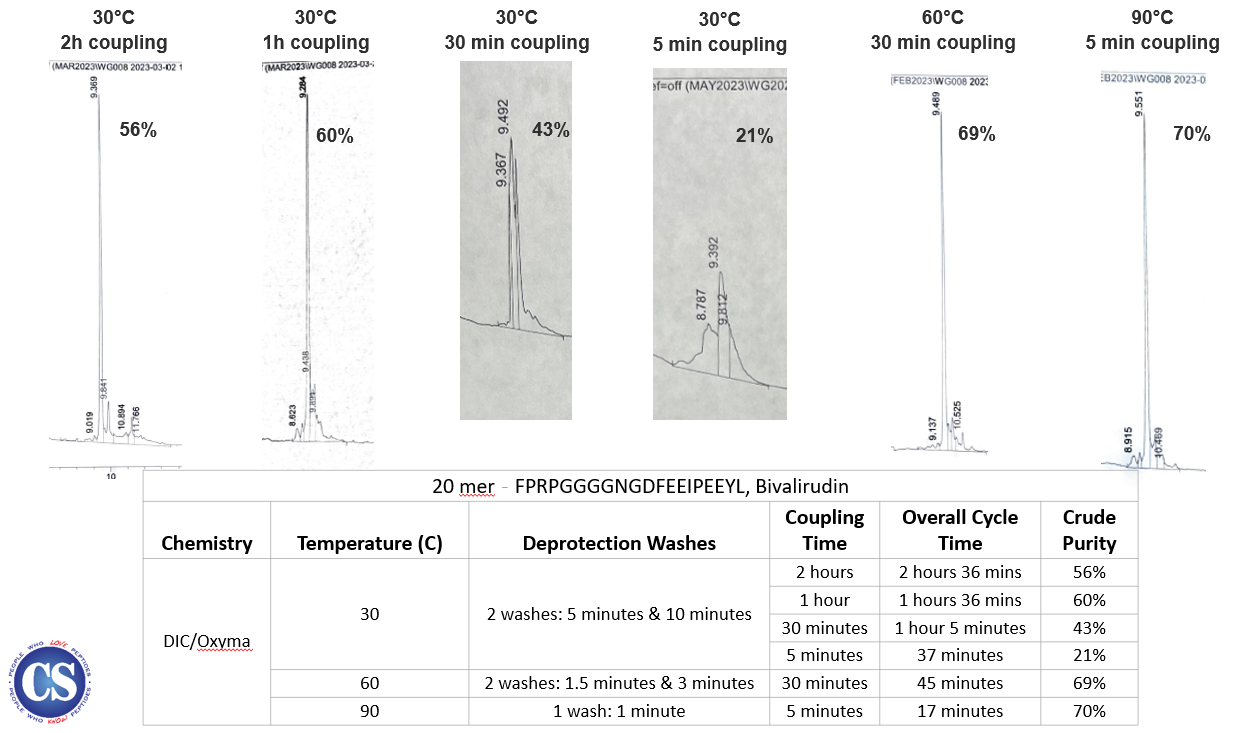

From the data, we can see that by

increasing the temperature, we are able

to reduce the coupling time to maintain

or even produce higher crude purity.

Additionally, if we maintain the same

temperature for the synthesis while

decreasing the coupling time, as

expected it will significantly

negatively impact the crude purity. As

evident more clearly as organized and

shown below with the crude purity

peaks.

Increasing the synthesis temperature

is the best way to optimize the overall

cycle time, allowing users to shorten

the deprotection and coupling phases of

synthesis, regardless of the chemistry

or individual peptide sequence.

About CSBio For over 30 years, CSBio,

a leading peptide and peptide

synthesizer manufacturing company

located in Silicon Valley, California,

has been providing cGMP peptides and

automated peptide synthesizers to the

global pharmaceutical community. CSBio’s

peptide products and peptide

synthesizers can be found in production

laboratories, universities, and

pharmaceutical companies

worldwide.

Interested in any of our peptide

synthesizers? Get

in touch with

us.

Comparison of Microwave and

Conduction Heating for Solid Phase

Peptide Synthesis

In collaboration

with University of California, Davis;

UCD evaluated microwave and conduction

heating and presented the findings at

the 28th American Peptide

Symposium

Abstract

Solid phase

peptide synthesis (SPPS) has become a

standard approach for synthesis of

peptides, especially in a laboratory

setting. Heating the reactions in SPPS

could significantly reduce the coupling

and deprotection times. One of the

heating methods is to use microwave

which is becoming increasingly popular

because it not only dramatically reduces

the synthesis times, but also increases

the crude peptide purity [1]. However,

microwave peptide synthesizers are

relatively expensive. In this study, we

investigated whether SPPS using

conduction heating can achieve similar

result as microwave irradiation. CSBIO

II and CEM Liberty Blue were used as

heating resource of conduction and

microwave heating, respectively. Four

peptides with length of 18mer, 19mer,

20mer (Bivalirudin) and 39mer

(Exenatide) were selected as examples.

The peptides were synthesized using the

same synthesis protocol at 90 ºC

including identical coupling,

deprotection and washing cycles. The

differences between the two approaches

are the temperature of washing DMF (90

ºC vs 23 ºC for conduction and microwave

heating, respectively) and overall

synthesis cycle time (17 min vs 13 min

in conduction and microwave heating,

respectively). Both conduction and

microwave heating generated comparable

results with crude purity of 52.0% vs

51.7%, 49.0% vs 57.3%, 62.8% vs 57.1%,

37.0% vs 30.5% for 18mer, 19mer, 20mer

and 39mer, respectively. One of the

advantages of conduction heating is the

uniformly and consistently delivered

temperature during the synthesis which

could minimize racemization and side

reactions caused by spikes and hotspots

typically associated with microwave

heating. In addition, conduction heating

is also a more cost-efficient heating

method when compared to expensive

microwave heating technology.

Download the

full poster here Download

Link

About CSBio:

For over 30 years, CSBio,

a leading peptide and peptide

synthesizer manufacturing company

located in Silicon Valley, California,

has been providing cGMP peptides and

automated peptide synthesizers to the

global pharmaceutical community. CSBio’s

peptide products and peptide

synthesizers can be found in production

laboratories, universities, and

pharmaceutical companies

worldwide.

Interested

in any of our peptide synthesizers? Get

in touch with

us.

Synthesizing a 132-mer peptide

with

high purity

Using a CSBio

research scale peptide synthesizer, we

share a case study of how a 132-mer

peptide can be synthesized with high

purity

Introduction

Synthesis of

peptides at any length requires extreme

attention to detail for accuracy and

purity of the desired compound.

Correctly synthesizing peptides of 50

mer length is difficult, over 100 mer

length is a remarkable feat. CSBio’s

fully automated instruments are

purposefully designed to maximize resin

and solvent interaction while

maintaining a clean system throughout

the synthesis protocol, making it

possible to consistently synthesize

peptides containing over 130 amino acids

at very high purities.

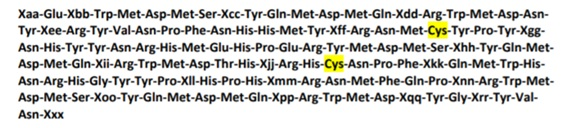

Brief

The chemists

in CSBio’s in-house cGMP peptide

manufacturing facility were tasked with

making a cyclic peptide 132 amino acids

in length containing a Cysteine to

Cysteine disulfide bond linking the 39th

and 79th amino acids.

132 AA peptide sequence

(protected)

Using

a research scale CSBio peptide synthesizer,

Fmoc protected amino acids were attached one

by one in a stepwise fashion. Engineering

decisions such as 180° inversion mixing as

well as dedicated lines to separate the

delivery of amino acids and piperidine

ensure more resin to solvent interaction

than nitrogen bubbling, vortex or

oscillation mixing, while also maximizing

coupling with no risk of chemical cross

contamination.

CSBio CS136X

Upon peptide synthesis completion the

resin was cleaved giving the chemist’s

620mg of crude at 75% purity. A portion

of the crude (220mg) was loaded into a

1” C18 HPLC column, cyclization of the

fractions was performed using an iodine.

Post purification the chemists were able

to extract 18mg of the re-purified

disulfide peptide which tested at 98.7%

purity. Resulting in an 8.2% yield from

crude for a compound whose molecular

weight was >15000g/mol.

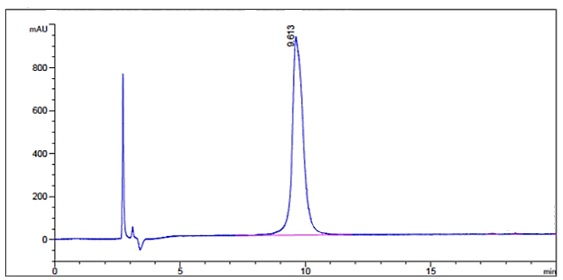

132mer post-purification

chromatogram

Conclusion

CSBio

synthesizers are designed to deliver the

user with the highest crude quality for

any possible peptide. As the only

automated synthesizer manufacturer that

produces cGMP peptides, constant

collaboration of in-house chemists and

engineers during the design process

enables CSBio to improve synthesis

results compared to industry

competitors; making CSBio synthesizers

the most robust and reliable instruments

on the market for synthesis of any

peptide.

Interested

in our research scale peptide

synthesizers? Get

in touch with

us.

A Practical Guide to Solid Phase

Peptide Synthesis (SPPS)

A 65 page guide

on the practical aspects of performing

SPPS

What

is this guide?

Written

through more than 60 years of combined

experienced in making peptides, this is

a 65 page practical guide on

SPPS.

The

purpose of this guide is two-fold.

First, a brief introduction on the

development and most common applications

of solid-phase peptide synthesis will

enable the user to best apply the two

most widely-used synthetic strategies –

Boc/Benzyl and Fmoc/tButyl chemistries –

to his/her projects. Second, a detailed

description of peptide synthesis,

cleavage, and purification in the

experimental section is given with

‘helpful hints’ so that newcomers to

peptide science will have easy access

and avoid some of the obstacles which

often lead to expensive mistakes and/or

poor synthesis yields

Introduction

Solid phase

synthesis is a process by which chemical

transformations can be carried out on

solid support in order to prepare a wide

range of synthetic compounds. This idea

was first developed by Bruce Merrifield

to synthesize polypeptides and earned

him the Nobel Prize in 1984. Solid phase

chemistry offers many advantages over

conventional synthesis in terms of

efficiency as well as convenient work-up

and purification procedures. In solution

phase peptide synthesis, particularly in

longer sequences, the repetition of

coupling and deprotection cycles can

become very labor intensive and require

the isolation of all peptide

intermediates.

I. A Brief

Historical Perspective The chemistry of

peptide synthesis – first developed in

the early 1900’s by Emil Fischer –

arguably marks the birth of organic

synthesis as we know it today. Whereas

the lion share of organic synthesis

continues to be performed by

solution-phase methods, i.e., with each

independent chemical reaction followed

by a purification step and

characterization of the resulting

synthetic intermediate, two

peculiarities of peptide chemistry

spurred the development of a more

efficient synthetic strategy. In

contrast to most total synthesis

efforts, the synthesis of peptides – at

least until the final deprotection step

– is an iterative process, with

alpha-amino (alphaN) deprotection and

amide couplings performed in succession

until the desired full-length target

peptide is obtained. In addition, most

peptides of biological interest are

grossly insoluble in most organic

solvents irrespective of side-chain

protection tactics. The net result of

these two characteristic features of

peptides was that the first sixty-odd

years of peptide synthesis forged little

ground until the landmark work in the

late 1950’s of R.B. Merrifield at

Rockefeller University.

During the

course of his Ph.D. work, Merrifield (a

biochemist) proposed an entirely new

paradigm in organic synthesis. As is

often the case when an outsider looks

into an insular field and pursues a tack

that is anathema to the existing experts

in the field, Merrifield’s idea of

performing all synthetic manipulations

using the C-terminus of the target

peptide linked to an insoluble solid

support was met with much criticism.

However, it was not long before the

chemistry of solid-phase peptide

synthesis (SPPS) was honed to a point

where traditional solution-phase

methodologies were no match with regard

to speed and versatility. The original

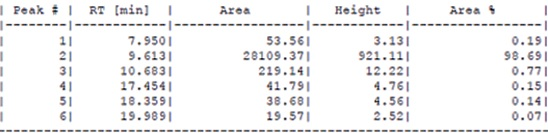

“Merrifield” version of SPPS – more

accurately referred to as Boc/Benzyl

chemistry – was roughly finalized in the

late 1960s, and employs a graduated acid

lability system for manipulation of all

protecting groups (Scheme 1). In this

strategy, the alpha-amino

t-butoxycarbonyl (Boc) protection is

removed with TFA, while side-chain

protections and the peptide- resin

anchorage (the linker) require much

harsher acidic conditions for cleavage.

This final step is accomplished using

liquid HF, a much stronger acid than TFA

(acidity functions of -11 and 0.1,

respectively).

Scheme

1 depicts the manner in which Boc/Benzyl

SPPS simplifies all of the reactions

involved in peptide synthesis by

allowing for purification via

filtration, so that excess reagents can

be employed and removed by simple

washing. It is important to emphasize

that the chemistry of SPPS is not

fundamentally different from that used

in solution-phase peptide synthesis. The

sole chemical distinction between

solution- and solid-phase peptide

synthesis is that the C-terminal

protecting group in the latter is

rendered insoluble by virtue of its

incorporation into a polymer. This

difference notwithstanding, all

side-chain and alphaN protecting groups,

as well as coupling chemistries,

employed in solid-phase synthesis have

been successfully applied in

solution-phase synthesis, and

vice-versa, with few

exceptions.

During

the 1970s several groups were actively

developing milder methods for SPPS that

avoided the use of liquid HF as for the

final deprotection/cleavage reagent.

While a variety of milder graduated acid

lability systems were devised, the

method that rose to general

applicability was the orthogonal system

of Fmoc/tBu chemistry. This strategy –

developed by R.C. Sheppard at Cambridge

University – differs from Boc/Benzyl

chemistry in that the side-chain and

alphaN protecting groups are removed

under conditions that leave the other

class entirely intact. In Fmoc/tBu

chemistry, a mild base – usually

piperidine (pKa = 11.1) – is employed

for iterative N

9-fluorenylmethoxycarbonyl (Fmoc)

deprotection, while global side-chain

deprotection/cleavage is accomplished

with TFA (Scheme 2).

It

must be emphasized that the more

traditional Boc/Benzyl and Fmoc/tBu

chemistries, while differing in chemical

minutiae, are fundamentally the same

process. In both cases, the target

peptide chain is assembled in a stepwise

fashion from alphaN- and side-chain

protected amino acids. In both cases,

the ‘transient’ alphaN amino protection

is employed solely during chain

elongation (the coupling reaction) and

then removed for the subsequent coupling

reaction. Lastly, in both cases, the

final step – global side-chain

deprotection and cleavage of the

peptide-resin anchorage – is

accomplished by acidolysis, and the

target peptide isolated by trituration

from ether and purified by

reversed-phase high performance liquid

chromatography (RP-HPLC).

Download the

full 65 page guide here: Download

Link

About CSBio:

For over 30 years, CSBio,

a leading peptide and peptide

synthesizer manufacturing company

located in Silicon Valley, California,

has been providing cGMP peptides and

automated peptide synthesizers to the

global pharmaceutical community. CSBio’s

peptide products and peptide

synthesizers can be found in production

laboratories, universities, and

pharmaceutical companies

worldwide.

Research Scale Peptide

Synthesizers:

Demystifying Purity, Synthesis Speed

and Waste Generation

Understand what

drives peptide synthesis purity, speed,

and waste generation

Introduction

Anyone

that has performed peptide synthesis,

either manual or automated, realizes

quickly that each peptide is different.

Peptide sequences can vary in length,

contain many different amino acids or a

few of the same, be soluble or

insoluble, contain disulfide bonds, and

many more. With any standard synthesis

protocol, the “easy” peptide results in

both high crude purity and high purified

product yield. While a difficult peptide

using a standard synthesis protocol

delivers crude peptides with low purity

that require more downstream work and

lower yields of the purified product (or

in some situations, no mass

identification of the target

peptide).

When

performing peptide synthesis, it is not

uncommon for a peptide containing only

10 amino acids to be considered more

“difficult” to synthesize than a much

longer 25+ amino acid peptide. Overall

success with synthesizing a specific

peptide is generally impacted

by:

-

Peptide Length: the total number

of amino acids in the peptide

sequence.

-

Peptide Sequence: the specific

combination and order of the amino

acids in the sequence.

-

Synthesis Protocol: The set of

steps that together add amino acids

to the peptide sequence. These

include deprotection washes,

coupling time, as well as the number

of cleaning washes after both

deprotection and coupling.

Of

these factors, the Synthesis Protocol is

the only way one can control the

conditions of their syntheses and

optimize their protocol to deliver pure

peptides in a time-efficient

manner.

Peptide

Synthesis Protocols

When making

a peptide, users must balance the purity

and yield while also optimizing for

synthesis speed and reducing waste for

their workflow. Heating the synthesis

can allow users to lower the times for

deprotection and coupling, leading to

faster cycle times. This can be done in

a variety of ways including conduction

heating and microwave heating. For the

best results, heating needs to be

delivered uniformly and to consistent

temperatures. Conduction heating is

scalable from 20 mL up to

commercial-size reaction vessels 500L+.

It avoids racemization caused by spikes

and hotspots typically associated with

microwave heating. Conduction heating is

also a much more cost-efficient heating

method when compared to expensive

microwave heating technology.

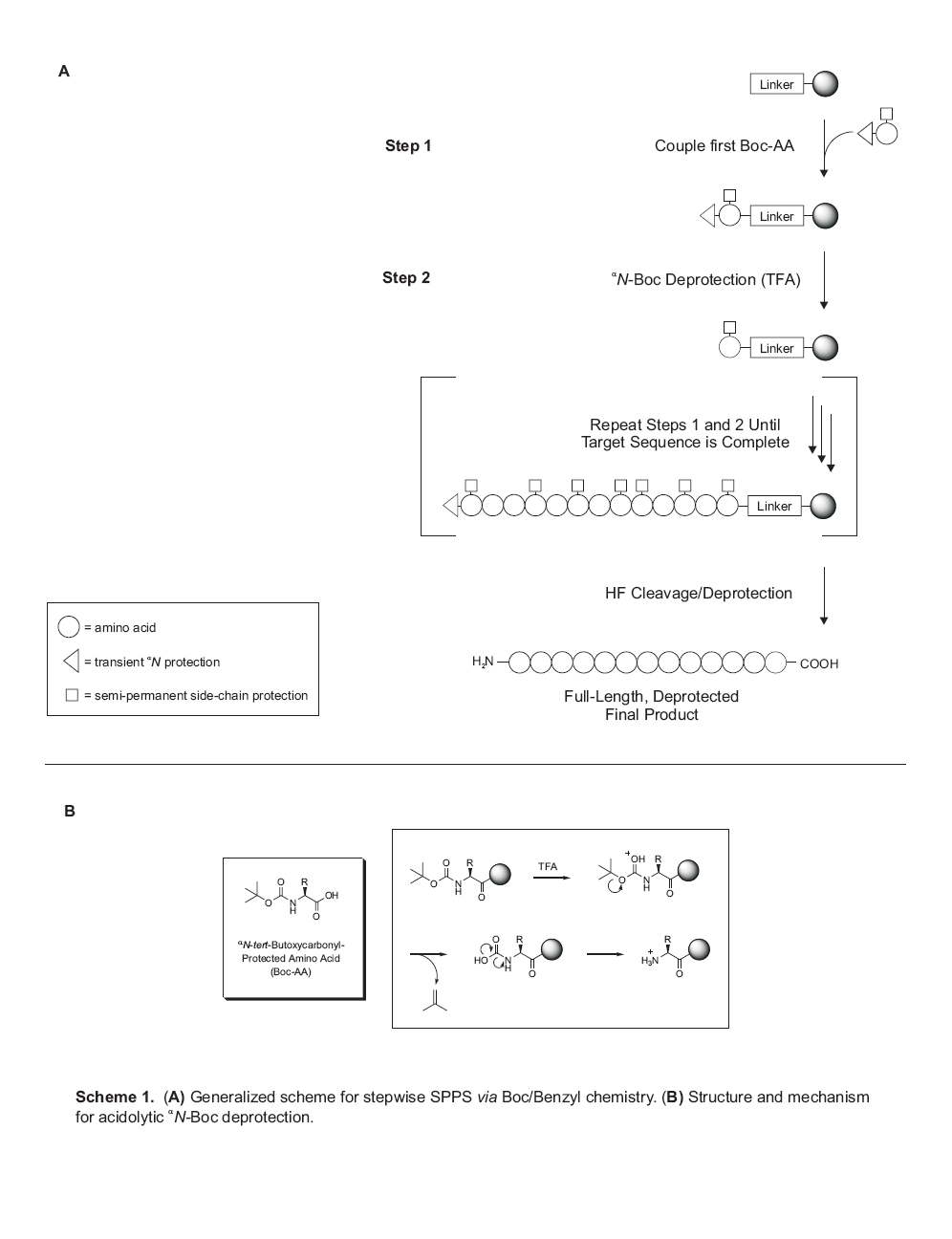

Synthesis

speed and waste also go hand in hand as

shown in the chart. It is easy to see

that if a protocol contains more DMF

washes, 8 vs 3, the protocol with 8

washes will be expected to take longer

and generate more waste.

That bodes

the question: Why do two instruments

aiming to complete the same objective

differ so much in their standard

protocol?

Higher

Purity - The protocol with 8 washes is

more likely to deliver a higher purity

peptide due to maintaining a cleaner

synthesis. The washes after deprotection

are essential for ensuring that all the

Fmoc group is completely gone before

coupling. Doing washes after coupling

ensure that your main peak will be your

main peak, leaving no room for

cross-contamination between amino acid

cycles. Look at our case

study of the synthesis of a

132-mer peptide on CSBio’s

research scale peptide

synthesizers

Universally

Applicable - A user also benefits from

an automated peptide synthesizer that is

preloaded with protocols that will work

well on nearly all peptides, regardless

of sequence or length. The protocol with

8 washes can be run on a wide range of

peptide sequences and expect a

successful synthesis, not for a fraction

of the peptide sequences. Users of the

CSBio Peptide synthesizers can easily

choose between a conservative or

aggressive washing protocol giving them

the ability to reduce the number of

washings after deprotection and coupling

to improve synthesis speed and reduce

waste.

Peptide

Synthesis - Synthesis Protocols and the

impact on Purity, Speed, and Waste

Generation

Cost

to Perform Peptide Synthesis

What’s the

raw material cost to run a peptide

synthesizer? Well, most research labs

will synthesize ~10 peptides a month at

the 0.1 mmol scale, usually averaging

about 15 amino acids in length. Then

it’s largely dependent on the synthesis

protocol utilized and the type of raw

materials used. Some peptide synthesizer

manufacturers require special amino

acids and resins to run their synthesis

protocol, such as His(Boc) that can be 7

times more expensive than standard

His(Trt), or PEG-PS resin that can be

twice as expensive as Rink Amide MBHA

resin.

When

considering the synthesis protocols, the

amino acids, resin, and all the reagents

and solvents, a typical cost per year

will range between $5k to $10k. This

considers purchasing the amino acids in

100g bulk (not pre-packaged cartridges),

and does not include any disposable or

consumable items that the synthesizer

manufacturer may require. If you're

interested in learning about the details

of the cost to perform peptide synthesis

and these calculations, just reach out

to us.

As users can

see, while there may be a marginal

potential cost savings from the reduced

waste of the microwave protocol, this

doesn’t factor in re-running the

synthesis in situations that the target

peptide is not found. Even without the

re-synthesis situation, looking at the

total cost per run is negligible when

factoring in the much higher purchase

price of an expensive microwave

synthesizer.

With a CSBio

Peptide Synthesizer, users are confident

that the provided protocols deliver

high-quality results on difficult

peptides while allowing users to easily

change the protocol to manage synthesis

speed and waste. Reach out to us at instrument@csbio.com,

schedule a

call to learn more,

or just ring us directly at +1 650 525

6200 if you’re interested in discussing

your peptide synthesizer needs.

About CSBio:

For over 30 years, CSBio,

a leading peptide and peptide

synthesizer manufacturing company

located in Silicon Valley, California,

has been providing cGMP peptides and

automated peptide synthesizers to the

global pharmaceutical community. CSBio’s

peptide products and peptide

synthesizers can be found in production

laboratories, universities, and

pharmaceutical companies

worldwide.

From peptide drug discovery,

through

process development, to commerical

scale manufacturing

In this case

study, we talk about CSBio's peptide

synthesizer platform

and knowledge that allows companies to

utilize our peptide synthesizers during

the early days of drug discovery, all

way through commerical scale

manufacturing

Introduction

When

a multinational pharmaceutical company

initiated their in-house

manufacturing of peptides in the early

phases of drug discovery, they came to

CSBio for their instrumentation needs.

As a manufacturer of custom peptide

synthesizers from small scale to large

scale manufacturing, this pharmaceutical

company knew they had a partner that

could meet all of their instrumentation

needs from drug discovery to commercial

manufacturing for process development

and scale up ease.

Brief

During drug

discovery

for lead optimization, this

pharmaceutical company determined they

needed a

reliable small scale synthesizer to

produce peptide analogs which would be

used

in testing to determine the best analog

for scale-up and clinical trials. As a

fair amount of material would be

required for this testing (20-100 mg)

and

flexibility in the synthesis protocol

was important, they turned to the CS136

which enabled their discovery lab to

rapidly synthesize dozens of peptide

analogs in a short amount of time with

enough material produced for multiple

tests and assays.

CSBio

CS136M

Once

a primary peptide drug candidate was

selected, the peptide chemists

at this pharmaceutical company were

tasked with making a continuous supply

of

high purity peptide for toxicological

studies, PK studies, formulation work

and

additional assay testing. Grams of

peptide were now required, so the

pharmaceutical company set up a CS536

system in the process development

laboratory to accomplish this

task.

To

manage the scale up transition from

small scale to large scale

manufacturing, a second CS536 system was

purchased shortly thereafter and

customized with both a 180° inversion

mixing system and overhead stirring.

This

unique design was a collaboration

between CSBio design engineers and the

pharmaceutical company to add an extra

layer of confidence in their methodology

as they prepared for the scale up

transition from inversion mixing to

overhead

mixing, which would ultimately be

required for large scale manufacturing

of the

peptide drug.

Custom

Designed CSBio CS936

As the

pharmaceutical

company moved into late stage clinical

trials the new task at hand was scaling

up for commercial manufacturing. CSBio

and the pharmaceutical company worked

closely together to design a CS936

production scale synthesizer that would

suit

their exact large scale production

requirements. It was imperative that the

transition from R&D scale to process

scale to manufacturing was as seamless

as possible. As all CSBio synthesis

systems use the same 21 CFR Part 11

compliant CSPEP software®, the

transition from milligrams to grams to

kilograms

was made much easier as the synthesis

protocols could be transferred up the

production scale.

The CS936

unit was synthesizing

manufacturing runs immediately upon

installation/operational qualification

as

there was virtually no learning curve

for the manufacturing group. CSBio has

purposely designed our systems to make

scale up from R&D to commercial

manufacturing as easy as

possible.

Conclusion

CSBio

provides customers with peptide

synthesizers that fit their exact

needs throughout the lifecycle, whether

it’s during early drug discovery or

late stage commercial manufacturing. By

working intimately with customers

coupled with over 30 years of peptide

and instrumentation knowledge, customers

can trust they have a partner to ensure

a successful project.

Interested

in any of our peptide synthesizers? Get

in touch with

us.

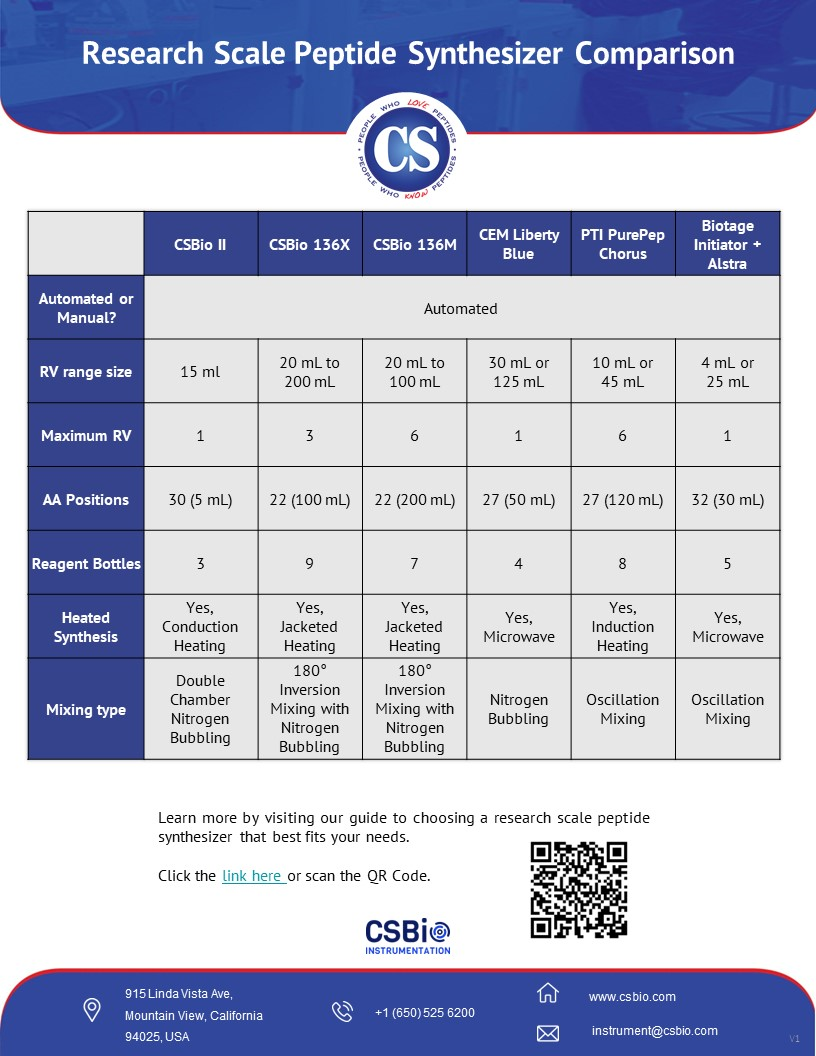

Research Scale Peptide Synthesizer

Comparison - A Guide to Choosing a

System that Fits Your Needs

We've gathered the key

things to know to adequately compare the

most popular synthesizers on the

market for users searching for a peptide

synthesizer.

Introduction

A major

reason medicinal

chemists and researchers love peptides

is they offer a unique ability to treat

unmet clinical needs in comparison to

small molecules and biological

therapeutics. With over 70 approved

peptide therapeutics on the market

treating

patients today, researchers are looking

for the next peptide therapeutic that

will make waves.

What about

synthesizing

the peptides that researchers use for

their studies? CSBio has been making

peptides and peptide synthesizers for

over 30 years, and we’ve developed

synthesizers for the first-time peptide

synthesis user as well as the advanced

peptide chemist. Here’s the major things

to consider when comparing research

scale peptide synthesizers for your

needs.

1. Manual

or Fully

Automated?

This day and

age, a

fully automated synthesizer is table

stakes. But making sure the synthesizer

you buy is fully automated is the most

important factor.

For those

that haven’t

made a peptide before, a typical solid

phase peptide synthesis protocol will

consist of deprotection cycles, multiple

washes, coupling, and more multiple

washes for each amino acid addition to

their peptide. Dependent on the peptide,

there can be multiple washes and

deprotection cycles to ensure adequate

synthesis, defined by high purity of the

targeted peptide being

synthesized.

Typical

Peptide

Synthesis Cycle for each Amino Acid

Addition:

2x

Deprotection

6x DMF

Wash

Coupling

2x DMF

Wash

When

performing manual

synthesis, the washes and deprotection

cycles are extremely redundant and time

consuming, requiring manual solvent

addition and draining for each wash or

deprotection cycle. Semi or manual

peptide synthesizers typically only

perform

the coupling step, and require users to

manually perform the remainder of the

synthesis. Given the coupling step is

the least labor intensive portion of the

synthesis and accounts for less than 10%

of the touch time, these peptide

synthesizers are categorized as manual

synthesizers.

What does it

mean to

have a fully automated peptide

synthesizer? Most peptide sequences are

around

20 amino acids long, and users would

like to be able to setup and walk away

from their peptide synthesizer and come

back to a completed peptide. This means

the synthesizer is able to fully

automate the completion of a synthesis

cycle

for each amino acid, as well as continue

to subsequent amino acids without any

user intervention such as adding more

solvents, reagents, or amino acids.

Having a fully automated synthesizer

that allows users to make an entire

peptide without any manual steps in

between is by far the most important

factor

to verify when buying a peptide

synthesizer.

Comparison

of Popular Research Scale Peptide

Synthesizers

Take a look

at our case

study of the synthesis of a

132-mer peptide on CSBio’s

research scale peptide

synthesizers,

which was performed entirely unattended

without any solvent

recharging, amino acid additions, or

manual steps.

2.

Reaction Vessel (RV)

Size

The reaction

vessel size

determines the maximum synthesis scale

that a peptide synthesizer is capable of

performing, and synthesis scale

determines the amount of peptide

material that

can be produced per synthesis batch.

Most peptide synthesizers consider the

solvent, reagent, and amino acid

consumption based on the reaction vessel

size

to ensure adequate unattended

automation; as users would not want a

reaction

vessel sized on a synthesizer that

requires solvent addition every 30

minutes.

Dependent on

what

quantities (mg to grams) a user requires

at their phase of research, determines

the size of reaction vessel. The amount

of peptide that can be produced in any

given reaction vessel can depend on many

factors including resin substitution,

chemistry, number of amino acid

additions, and expected growth. Some

manufacturers only talk about synthesis

scale based on mmol, but it’s difficult

to compare when there are so many

factors that determine mmol outside of

reaction vessel size. To provide a rough

idea, a 15ml reaction vessel can be

used to produce anywhere from 50mg to

500mg dependent on these many factors.

For a 20-mer peptide, using 0.4

mmol/gram substitution resin, a 0.1mmol

synthesis can be performed with a 15ml

reaction vessel producing ~300mg of

crude peptide. Upon purification,

dependent on purity requirements, this

crude

peptide can generally yield ~100mg of

pure peptide.

3.

Purity, Synthesis

Speed, and Waste

Generation

After

determining the

quantity of peptide required, a few

other practical questions to ask when

deciding on a peptide synthesizer is how

many peptides will you make per month,

and at what purity will you need for

these peptides? Most research scale

peptide

labs are synthesizing around 10 peptides

per month, and purity requirements can

vary but 90 to 95% is typical. With

these requirements, ensuing a high

quality

crude peptide leads to ease of

purification.

What are the

factors

that drive a high quality crude peptide?

It comes down to the peptide amino

acid sequence, the length of the

peptide, and the synthesis protocol.

With an

“easy” peptide, a fast protocol with low

waste generation can yield a high

quality crude peptide, while a

“difficult” peptide with that same fast

protocol

can at times not even yield the correct

target peptide (as identified by mass

spectrometer) within the crude

product.

The

synthesis protocol

itself is also the primary driver when

it comes to synthesis speed and waste

generation. As such, many times there’s

a trade-off between synthesis speed,

waste generation, and purity. Take a

look at our article Demystifying

Purity, Synthesis Speed

and Waste Generation that talks in detail about this.

4.

Chemistry Flexibility

For most

users making

peptides, the desired goal is to simply

produce their target peptide, where

having an easy to use peptide

synthesizer is more desirable than

having a lot

of features which can increase

flexibility, but also add

complexity.

For the

advanced peptide

chemist, there may be a desire to have a

lot of flexibility in performing

different types of chemistry to improve

synthesis yield, or to be able to

develop a process for scale up. This

flexibility could be performing double

couplings, cappings, doing Fmoc

synthesis, Tboc synthesis, using DIC

coupling

or HBTU coupling within the same

peptide, to name a few.

While there

are many

detailed factors to consider that will

drive this flexibility, primarily

related to the software interface and

how system functions are performed, a

major factor is whether the system has

the dedicated reagent bottles available.

To perform DIC coupling on one amino

acid addition, followed by HBTU coupling

on the subsequent amino acid addition in

the peptide sequence, requires the

dedicated reagent bottles to be able to

perform this in a fully automated

manner.

These are

the top things

to consider when looking for a research

scale peptide synthesizer. There are

many other considerations as well, such

as:

Cost of the

synthesizer,

as well as cost of long term ownership

when it comes to reliability and ease of

repair and maintenance

Performing

chilled and

heated synthesis

Performing

high

throughput synthesis if a large quantity

of peptides is required on a weekly

basis.

Scale up

considerations,

where users will desire to establish

processes on research scale systems to

move towards pilot and commercial scale

peptide production.

Reach out to

us atinstrument@csbio.com,

schedule a

call to

learn more, or just

ring us directly at +1 650 525 6200 if

you’re

interested in discussing your peptide

synthesizer needs.

About CSBio:

For

over 30 years, CSBio,

a leading peptide

and peptide synthesizer manufacturing

company located in Silicon Valley,

California, has been providing cGMP

peptides and automated peptide

synthesizers

to the global pharmaceutical community.

CSBio’s peptide products and peptide

synthesizers can be found in production

laboratories, universities, and

pharmaceutical companies

worldwide.

|

沪公网安备 31011502005552号

沪ICP备13005633号-1

沪公网安备 31011502005552号

沪ICP备13005633号-1